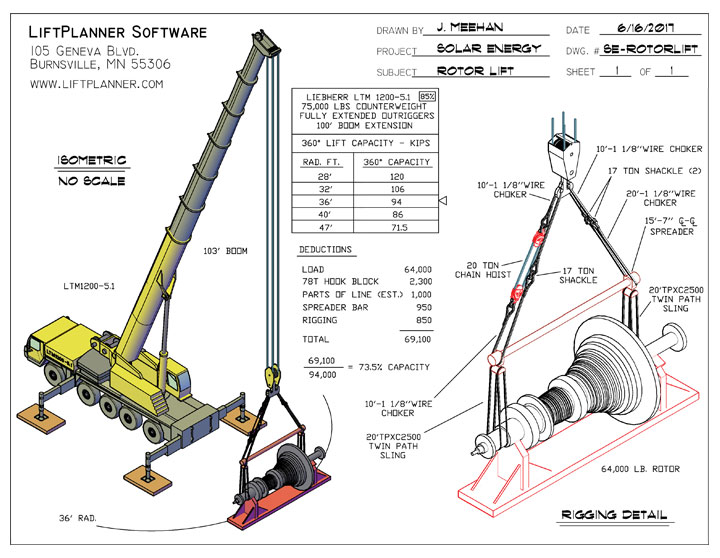

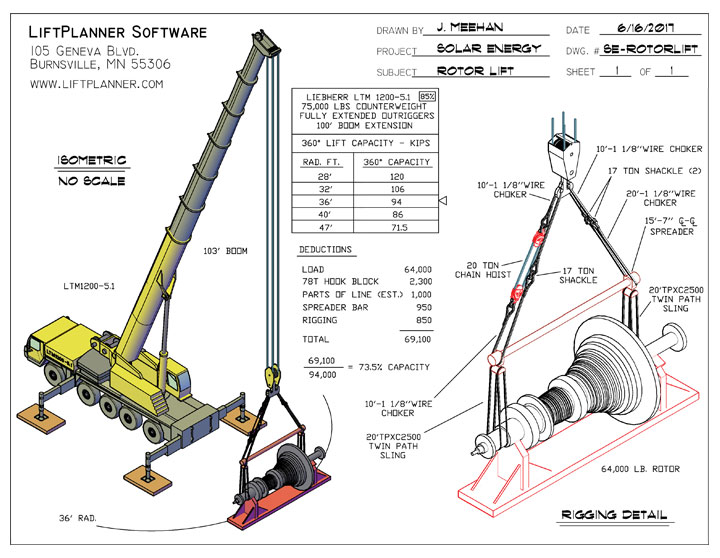

If the actual information at the lifting site does not tally with the lifting plan, you should stop the operation until the plan has been updated and re-approved. You should never deviate or vary from the approved lifting plan. Details of Loads Load Position 1 Load Position 2 Load Position 3 Weight: Dimensions: Position of C of G: Height of lift (worst case only): Max. Sketch of the lifting zone (showing position of lifting equipment, crew and load) and Description of lift: NB 50 reduction in load capability if man basket is used. Crane Standard Lifting Condition Remark (75 criteria of lifting capacity on the load chart) Working Crane Model & Capacity ( Ton) m Radius Outrigger Length Lifting Height m Type of Load Shape Main Block / Axillary Hook Capacity (SWL) Ton (Tick one) Load L: ( m) x W m Dimensions H: ( m) Load Weight Ton Counterweights Ton Hook/Rope Ton Max. Engineering calculation for lifting beams. Requirements to erect or dismantle lifting equipment (if any) Lift plan submittal with drawings(to be placed in cab of crane before lifting operation begins). Lifting crew (including their roles and competencies). Your lifting plan should include, but not limited to, the following elements:

If the actual information at the lifting site does not tally with the lifting plan, you should stop the operation until the plan has been updated and re-approved. You should never deviate or vary from the approved lifting plan. Details of Loads Load Position 1 Load Position 2 Load Position 3 Weight: Dimensions: Position of C of G: Height of lift (worst case only): Max. Sketch of the lifting zone (showing position of lifting equipment, crew and load) and Description of lift: NB 50 reduction in load capability if man basket is used. Crane Standard Lifting Condition Remark (75 criteria of lifting capacity on the load chart) Working Crane Model & Capacity ( Ton) m Radius Outrigger Length Lifting Height m Type of Load Shape Main Block / Axillary Hook Capacity (SWL) Ton (Tick one) Load L: ( m) x W m Dimensions H: ( m) Load Weight Ton Counterweights Ton Hook/Rope Ton Max. Engineering calculation for lifting beams. Requirements to erect or dismantle lifting equipment (if any) Lift plan submittal with drawings(to be placed in cab of crane before lifting operation begins). Lifting crew (including their roles and competencies). Your lifting plan should include, but not limited to, the following elements:

load capacity chart, range diagram, rigging method)įor complex lifts, additional engineering design efforts are necessary to ensure that the lifting operation is conducted safely. Safe work procedure or method statement.Lifting plan supported by a risk assessment (RA).

For example, a lifting plan would ensure that the crane is safely deployed and operated, and the lifting crew are clear about their roles and responsibilities.īefore you start any lifting operation, you must prepare the following: A lifting plan provides a systematic approach towards planning a lift and ensures that the lifting operation is properly managed.

0 kommentar(er)

0 kommentar(er)